Wax is back: Detroit is poised to be one of the country’s premier manufacturers of vinyl records

With the new Third Man Pressing joining the more than 50-year-old Archer Record Pressing, two of about 20 pressing plants in the entire United States are now located in Detroit.

Aretha Franklin. The MC5. Eminem.

Henry Ford. Louis Chevrolet. Horace and John Dodge.

Tunes and cars. Few things go together so well and even fewer stand out as defining features of the city of Detroit these last 100 years. In 2017, it’s still music and manufacturing that help shape the city and its place in the world.

For over 50 years, Archer Record Pressing has been pressing vinyl on the city’s east side. In its five decades of operation, Archer hasn’t had a single competitor in the city. In Owosso, Michigan, there was American Record Pressing, which started in Detroit as Vargo Inc., but the two companies’ time in Detroit never overlapped.

Archer has been the only game in town since 1965—until this year.

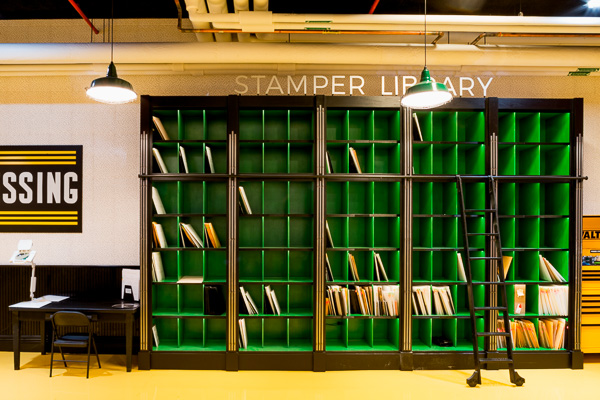

In February, Jack White’s Third Man Records celebrated the grand opening of Third Man Pressing, a vinyl pressing facility located in the back of the Third Man retail store on Canfield Street. Third Man boasts eight brand new vinyl pressing machines, the first such machines to be built in nearly 40 years. German manufacturer Newbilt Machinery built ten, of which Third Man bought eight.

Mike Archer, the third-generation owner of the family business, isn’t worried about competition—not at all. Archer attended the Third Man grand opening and has often talked to them about the industry. The vinyl pressing business is so robust these days that a new place in town shouldn’t affect Archer much, even if it does have twice as many pressing machines and all the flair of being owned by a hometown hero and rock star.

“It’s not really going to hurt us. There might be some juggling a little bit, but we respect what they’ve done over there—no doubt,” says Archer. “And I think it’s a mutual respect. If it is a competition, it’s a friendly competition. And I wouldn’t even call it a competition. They’ll do their thing and we’ll do our thing.”

While vinyl record sales are nowhere near what they were in the 1950s, 60s, and 70s, a resurgence in the popularity of vinyl records combined with a fraction of vinyl pressing plants still open has created a bottleneck in the supply chain. Archer estimates that it currently takes eight to ten weeks to get through back orders. Business is so steady that Archer will even turn orders down.

He has a policy for such situations: Detroiters get preferential treatment, then Michiganders, and then Midwesterners. “We’re rooting for the home team,” he says.

Both Archer and Third Man believe that the younger generations’ interest in vinyl will be steady for some time. Roe Peterhans, manager at the Third Man Detroit complex, says that in response to growing up with an increasingly digital entertainment world, the younger generations are searching for more tactile and kinetic experiences.

“There’s this wonderful problem of a lot of demand and not enough supply,” says Peterhans. “If we could just contribute a little bit to that supply and help that artist, help that label, help that one kid that’s trying to put something out on vinyl for 200 records to sell them at his shows, we’re here to do it.”

The whole Third Man Pressing operation is designed to increase interest in the vinyl experience. The pressing facility is bright, clean, and relatively quiet. A large window connects the plant to the Third Man record store, where patrons can watch records being made—sometimes the very records they end up buying. Workers in matching, crisp uniforms operate the machines by hand. Tours are also available.

Third Man hired 15 employees to staff the plant, all of whom had to be trained to operate the large machines. Eddie Gillis, the production manager, immersed himself in learning the new machines, whose designs, he says, are based on old machines but with improved technologies.

“Production is production. It doesn’t matter what you’re making, if you’re manufacturing toys, food—it could be anything, really. It comes down to enticing those machines to do what you want them to do,” says Gillis. “But the creativity is still there. You’re making these things by hand. It’s not fully automatic. There is a little bit of what someone has described as a black art to it, where you’re pulling something creative out of a machine.”

While the final product may be the same, the Third Man and Archer experiences couldn’t be more different. Third Man is located in the trendy Midtown shopping district, and its pressing plant is designed with spectators in mind.

Archer, on the other hand, is old school manufacturing, Detroit-style. Drive down Davison on the city’s east side and the small, non-descript building is easy to miss, mixing in with the old tool and die shops that line the street. Inside is a manufacturing facility evident of its fifty year history, as gritty and soulful as one might expect.

With roughly 20 or so vinyl pressing facilities left in the United States, to have two now located in Detroit is a major boon for the local music industry. Robert St. Mary recently started the small independent record label Hold Fast Vinyl, which has released 45s by M.C. Nightshade & the Theatre Bizarre Orchestra and Duende!. The label is preparing to release a third by Her Dark Host.

St. Mary says there is a great advantage in going with the local vinyl pressers: you can watch your records being made and then can pick them up yourself to cut out shipping prices.

And there, too, is that great Detroit connection, says St. Mary.

“A manufacturing facility that handles arts and culture at the same time—it marries the two great pieces of our story together.”

All photos by Nick Hagen.